#branded down jacket manufacturer

Explore tagged Tumblr posts

Text

Why You Should Layer With Modern Down Jackets This Winter?

As a retailer, hoping to wholesale purchase,then go through this to know why you should make down jackets your winter wardrobe staple.

#branded down jacket manufacturer#bulk winter coats#coat manufacturers russia#coat manufacturers uae#coat manufacturers uk#coat manufacturers usa#coat suppliers in Canada#custom down jacket canada#down coat manufacturers#down jacket manufacturer usa#down jacket suppliers

0 notes

Note

Max’ merch got me thinking that he’d love so much when his girl would wear his clothes. She always complains he actually has so much of red bull’s merch and she loves it on race weekends but not always. Kind of a girlfriend effect too because I can see him buying more ‚normal’ clothes. She loves to wear his buttons up in the mornings and his hoodies, jumpers in the evenings. And he always goes feral when he sees her

more soft bf max <333

i kinda love his merch. i wanna order some and see how it is from a manufacturing standpoint. i got some enchante chalet tees and they r nice but honestly super big compared to all my other tees so i wanna see how max’s compare

she loves the pride he has in his team and wearing his own merch branded with a number one, loves to steal his hats and shirts so she can show her support and that would drive him crazy, especially when they’re out and she steals the cap off his head and puts it on her own. but she also loves when he swaps out his team polos for a sweater or a nice button down. like she always compliments him but it’s different when she grabs the lapels of a new jacket and pulls him in for a kiss, before pulling away and telling him to turn around and whistling as he does so.

could see him buying clothes bc he wants her to be impressed with him !! like she compliments him on a specific color and he buys more things in it and every time she’s like “wow have i ever told you i love that color on you? my handsome boy” and he’s the happiest he’s ever been. except for maybe when he sees her in his clothes and he teases her for wearing it better than him.

she always steals his shirts to sleep in, and lounges around in his hoodies. would be late many mornings because he wakes up and finds her in his shirt from the day before and it still smells like him for the most part but her perfume has rubbed off on it and he can’t help but keep her in bed as long as possible

she’d get cold in the garage and disappear, so he’s looking around for her and starting to panic when she returns swaddled in one of his hoodies, and he just starts smiling like an idiot bc he’s just so overwhelmed with how much he loves her.

73 notes

·

View notes

Note

I was making tiny clay cats earlier and had a great idea for an ask, but then I got busy and forgot

I think it was something about fashion with the mass effect species

Electronically sending you a fictional tiny clay cat statue

Thank for the tiny clay cat, I'll put it on the virtual table that I keep in this blog at all times, which is a real table that happened to have a unique eco-friendly design, from an eccentric manufacturer, and definitely not just two logs I lugged from the woods.

🕔

🌱🐈 🪟🏙

🪵���� 🧺 🩲 🪤 🐁

I hope my virtual son 🧒 (common) ×1 doesn't knock it off with his virtual ball ⚽️ (common) ×1 because I won't financially recover from the purchase of the virtual gold 🪙 (rare) ×99 I'd need to glue the pieces of the broken clay cat back together in order to teach him about Kintsugi, the value of history and taking pride in the scars it leaves on ones body.

But yes, Mass Effect alien species fashion.

I mentioned before that the asari would definitely be into human fashion since we share a similar physical build.

They tend to mix up the centuries, however, wearing Edwardian era garments one day, and then full-on ancient Rome with draped tunics the next one.

To us, that seems silly because it's our history. These fashion designs are centuries old, and our first ever impressions on them were in textbooks or some other non-fashionable place. You wouldn't have a woollen toga at a strip mall where tweens naturally went with their overbearing parents to develop a sense of style.

But to the asari, all of these clothes are brand new! Just in! The latest fashion trends! From the perspective of their timeline, their society started integrating skinny jeans at the same time as robe à la française.

And the fact they live for 1000 years, the entirety of human recorded history is just two asari generations—would help them see our ancient fashion as more of "last Wednesday's"

Although many human cultures do keep their tradition clothes alive, like the hanfu being used in Chinese festives, or the Arab thawb still worn as in commonplace same as it was in 600 AD.... because what other garment is more suitable for desert climates?

Okay back to aliens, my fashion hyperfixation is showing

The asari are easy peasy, it's like two sister civilisations deciding to share their wardrobes and doubling the amount of clothes they retroactively have access to now.

You see many humans on the Citadel adapt to asari fashion, and as the game progresses, you notice asari fashion start getting influenced by predominantly human-fashion traits. Take Ryder's clothes in Andromeda for example.

The Alliance uniforms must seem ancient to the new humans with their cross-species influenced fashion trends, and I do mean ancient.

They probably view them (alongside our current modern hot-trendy fashion), like how me and you view the Victorian era fashion through a thick lens of rose-tinted glass. I wear corsets over flowy blouses, corsets, the thing that used to be considered underwear.

It's just very socially accessible now. Would someone someday wear a 2000's cheetah print thong over their military uniform in the alliance and call it fashion? Who's to say.

You see those modern two-piece suits with neon vibrant colours? The ones with precise cuts, invisible stiches, and all the pieces—down to the jacket buttons—are made from the same exact material and colour?

Someone is gonna dig that up in the year of Mass Effect and call it vintage and it's gonna piss me the fuck off, the trajectory of the earth will be altered from the massive rolls I'll be doing in my grave.

For the rest of the species, I don't see them adapting our garments due to anatomy incompatibility.

But fashion is the keyword here, because it is so much more than just clothes.

None of the asari have eyebrows, they don't have the genes for hair, therefore no eyebrows or anything.

Except, Liara, who has drawn-on (or perm tat) eyebrows.

Which is a VERY human feature, eyebrows might as well be the trademark of humanity. What do you do to an animal in animation to humanise it and make it seem intelligent?

You add eyebrows.

Liara, this rando asari scientist, for some reason, is elbow-deep into human makeup. Literally, no other asari has eyebrows or showed care for human makeup besides her.

We humans can't see our own "invisible" stripes, our faces are usually a blank canvas, which is why makeup is so fun, pretty, and whimsical. It's the same reason you'd add flowers to your hair or draw at the empty corner of the page.

Asari have their own seemingly natural face markings (unless those are drawn too) and putting makeup on top of them might seem distasteful or even tacky. Like drawing over someone's complete drawing.

But you know which species LOVES adding lines to their face? None other than space birbs themselves, the humble turians.

Humans like sunsets, birds like shiny things, and turians love glitter.

Of course, there are zero evidence of that ingame because they wanted the turians to have a metal, baddass, slightly scary aesthetic, and that's fair.

But if we're being realistic, it's just a matter of time before a turian decides to incorporate glitter into their clan face paint. It's a natural instinct for them to be the bird with the shinest, puffest, most colourful coat of feathers in the room.

Turians would love human makeup, wasn't it for the fact it's deadly toxic to them. Thanks, dextro. I mean, not like that ever stopped humans before. Remember when lipstick used to contain lead and mercury? Good time, good times.

But actually, now thinking about it, would those things be poisonous to them? Lead and mercury? I mean, they're already radioactive with a shit ton of copper in their bloodstream. Their body literally grows metal on their faces... and turian seminal fluid is poisonous to humans, meaning...

They might be able to use mineral based makeup! Which is so fucking deadly to humans, but probably fine for turians.

Although the human skin is spongey, the creamy make-up sticks to the top of it like icing on a cake. But it might not latch onto rough metal, aka turian plates.

It's also made with so many oils in mind because humans are actually very slimy, we just never notice it because our pores are so small and the thin layer of oil is hardly noticeable.

It's why bugs find us disgusting and wash our oill off of them after touching us, too bad they still need our delicious nutritious dead skincells and sweat to slurp up, so they endure it for the sake of food.

But we do, in fact, require being moist 24/7. It's where the "soft" skin feeling comes from, silly, being drenched in oil throughout your whole existence does that sometimes.

And turian metals do not, actually the oils might just bleach their shells if left to oxidise.

No, turian makeup wouldn't work if it was creamy or liquidiy like ours—even with the added lead.

My proposal: Chalk Makeup.

It's dry, it's crumbly, it's easy to remove. You ever drawn with chalk on street concrete? Would probably be the same as applying makeup to a turian.

And it has calcium! Yummy yum! Which the turians probably need a shit ton of, considering that most creatures with some kind of shell do insatiably crave it (see: sanils)

My last nugget of wisdom is that what's considered fashion to the geth/ai/synthetics in general isn't that far off from high-end, very personalised custom gaming pcs. Be it the pastel and white hardshells or the neons and glowing cooling liquids.

Hipster geth prefer the fruitger ero early 2010's aesthetic, enjoy that mental image for a while.

18 notes

·

View notes

Text

The Enduring Appeal of Keanu Reeves He battles evildoers in 'John Wick 4,' manufactures two-wheel pieces of art, and is worshiped by the internet, but Keanu Reeves swears he's just a normal guy. And he’s got the scars to prove it. Ky HendersonMar 15, 2023 9:00 AM EDT It’s easy to look cool when you’re riding a motorcycle, but it’s hard to look cooler than Keanu Reeves on a brisk, sunny afternoon in Los Angeles. He rests his left hand on his thigh and steers with his right, which gooses the throttle as he weaves around slow drivers. He wears a form-fitting black canvas motorcycle jacket that accentuates how trim he is—even more fit than he appears on-screen—and a beat-up Shoei helmet. He leaves the visor up, choosing instead to shield his eyes with sunglasses the Terminator might wear to a Hamptons garden party. Reeves looks at home and at ease on a motorcycle. He looks cool.

At a gas station stop, he suggests switching bikes. We’re each riding cruisers made by Arch, the motorcycle company Reeves co-founded with designer Gard Hollinger in 2011. The company produces high-end, highly personalized production bikes; I’m on a 1s, the company’s new $100,000+ sport cruiser. Reeves is on an older model, KRGT-1, but it’s his personal Arch, a true one-of-a-kind. It's the only Arch ever painted YK Blue, a color Reeves and Hollinger commissioned based on the ultramarine pigment famously mixed by mid-century French artist Yves Klein. Reeves says all that’s left of the paint is in a tiny can stored somewhere at Arch in case the bike’s paint ever needs touch-ups.

Which it most certainly would if, let’s say, some idiot were to put the bike down in front of a horrified Reeves while riding down the Pacific Coast Highway. Thankfully, there’ll be no lowsides today. Although the bike is beefy, with a 2,032cc V-twin powerplant, it’s easy to maneuver and comfy as a BarcaLounger.

Keanu Reeves stands in motorcycle factory holding blue mug Brian Bowen Smith

Reeves eventually leads us back to Arch’s factory building, which is nondescript from the outside but artfully decorated inside using shipping containers to separate working areas. Metal fabrication is done behind one; customer bikes are lined up in another with technicians hard at work. After Reeves dips outside for a cigarette—the 58-year-old both looks like a much younger man and smokes with the frequent abandon of one—he leads us to a small conference room.

“I like meeting people, but I’m a little reserved,” he warns as he settles into an office chair, looking far less comfortable than he did on a motorcycle. “How much of my private life do I want to talk about? I don’t know. Otherwise, let’s hang out.”

When Reeves was growing up in the Yorkville neighborhood of Toronto, he was consumed with existential thoughts. He discussed death a lot more than the average 11-year-old, for instance—but not because he wanted to die. He just wanted answers to big questions. Perhaps not entirely unrelated to his interest in mortality, he was also obsessed with the biker gangs that periodically motored into the neighborhood. It wasn't pods of dentists letting loose on weekends. It was leathers, patches, menace—the whole deal. And Reeves loved it.

“They looked exotic,” Reeves says. "They looked to me like they were free. Plus the bikes were cool and sounded great.”

Despite his childhood fascination, Reeves was in his early 20s before he first rode a motorcycle. It happened at a movie studio in Berlin—where else?—when he saw a woman on an off-road enduro bike in a parking lot. He approached her and asked if she’d teach him to ride, which she agreed to on the spot. (If you’re wondering why a woman would do that for a total stranger, search “Keanu Reeves in the 80s” in Google Images.)

Not long after he got back to Los Angeles, he bought a 1973 Mk2a Norton Commando, having long admired the classic brand. That bike currently sits in the Arch shop, which is notable for two reasons: One, few longtime riders are lucky enough to be able to hold onto their first bike. Two, over the years Reeves has…suffered some mishaps.

“Yeah, I’ve fallen off a few times,” he admits of the accidents he’s had on a variety of bikes. He takes a swig of water, then corrects himself. “Not ‘fallen off.’ Crashed. I’ve got a couple of hit-by-cars. A couple of going-too-fast. I’ve laid a couple of bikes down but I was riding in the winter, so that’s not really ‘crashing.’ That’s about it. The usual stuff.”

He’s broken ribs, knocked out teeth, sliced his leg open so deep that bone was visible. His most spectacular accident occurred in 1988, only a couple years after that day in Berlin. Reeves was riding alone at night in Malibu’s Topanga Canyon when he took one of the twisties too fast. By the time he came to a stop, he was lying on the pavement wondering if he was about to die. As you know, he didn’t—but he did fuck himself up pretty bad.

“I ruptured my spleen,” he says matter-of-factly. The widely reported version of the story goes that he needed the organ removed, but Reeves says it’s still intact. “They sutured it up and put a Band-Aid on.” He has a gnarly scar running vertically from his sternum down to his belly button, but in the right light it just ends up accentuating his abs because, well, he’s Keanu.

Reeves first met Hollinger through a mutual acquaintance about two decades after that crash, when Reeves wanted a custom sissy bar—basically, a backrest for a passenger—added to his 2005 Harley Davidson Dyna. Hollinger, who at that point was a relatively well-known, well-respected customizer with his own small LA shop, wasn’t interested.

“I knew I could build him the world’s most expensive sissy bar,” Hollinger says, “but I also knew it wouldn’t be satisfying for either of us.”

Instead, Hollinger spent the next five years completely reimagining the bike. He’d work in spurts, changing or adding something, then handing the bike back over to Reeves for months. By the time the bike was finished, Hollinger says, about the only parts of the original Dyna still remaining were the engine and the serial number on the chassis. Today that bike—a chromed-out ride fit for Mad Max—is displayed in the shop, the inspiration for what eventually became Arch.

Keanu Reeves on motorcycle wearing black canvas jacket and sunglasses Brian Bowen Smith

Eventually being the key word. When, during the long process of modding the bike, Reeves first suggested to Hollinger that the two team up to start a motorcycle company, Hollinger didn’t have to think about his answer.

“I knew what a tough business it is, what a challenge it would be—and that it would not be a great investment,” Hollinger, now 63, says with a laugh. “It was a wonderful motorcycle I built and it was wonderful getting to know Keanu, but starting a motorcycle company sounded like a horrible idea.”

Reeves didn’t relent. As the pair became better friends—and as the motorcycle continued to take shape—they’d have long conversations about the realities of starting the company. Hollinger would show up to their discussions with pages of questions written on a legal pad, but what gradually eroded his hesitation was the thoughtfulness with which Reeves described the experience of riding a motorcycle.

Finally, nearly convinced, Hollinger asked Reeves to boil everything down to one reason why they should do something as seemingly crazy as starting a motorcycle company. The actor came up with it on the spot—a reason Hollinger immediately understood, which allowed him to envision the company and its worth as an opportunity to do something meaningful and long-lasting.

“Because,” Reeves told him, channeling the mortality-obsessed 11-year-old kid gawking at dudes on motorcycles, “we’re going to die.”

Related: 2023 Arch 1s Sport Cruiser Is the American (V-twin) Dream

There have been many jokes made over the years about Reeves being a dummy, but after spending about 8 seconds with the guy it’s obvious he’s keenly intelligent. I mention that I read lots of sci-fi and fantasy books as a kid, which prompts him to ask whether I have opinions on several titles, followed by recommendations to read several others.

Thing is, his idiosyncratic public persona—which is sort of like Ted (not Bill) if Ted were a little more shy and a much better dresser—isn’t an act. Reeves isn’t trying to fool his critics or fans. And he isn’t really putting on an act in an attempt to prevent people from knowing who he is. He’s just this very singular, introspective, likable person who happened to become a pop culture icon.

All of that said? He can be pretty goofy. His physical mannerisms are sometimes at odds with what he’s saying, like he’s being controlled by feuding puppeteers. He speaks haltingly, stopping and starting and stopping again, often all in the same sentence, as he considers what exactly he wants to say or, just as likely, what he doesn’t want to say. More than once over the course of an afternoon he giggles—yes, giggles—at something he says or thinks, placing his cupped hand over his mouth like a theatrical school child hiding laughter; the gesture is as strange as it is endearing. He's somehow both laconic and verbose, calm and keyed up.

Although Reeves has long been known as “The internet’s boyfriend,” he’s currently dating—sorry, internet—acclaimed visual artist Alexandra Grant. The pair first collaborated on the 2011 book Ode to Happiness after having known each other previously; in the following years they collaborated on other projects and co-founded the small book imprint X Artists’ Books. Their romantic relationship began about five years ago but only became public knowledge two years in, when they arrived at a red carpet event together.

When asked about Grant, Reeves leans back in his chair as though trying to put both metaphorical and literal distance between himself and the idea of discussing his personal life.

So, uh, maybe it’s best to make it about bikes: What’s Grant’s opinion of Reeves’ (occasionally injurious) motorcycle fixation?

“She used to have a motorcycle, so she’s fine with it,” Reeves says. Then he pauses, as he so often does, seemingly considering whether to say anything more. “She hasn’t ridden in a while.”

Despite his lifelong love of bikes, Reeves hasn’t ridden them much in his movies. There’s a brief scene in the landmark 1991 indie film My Own Private Idaho. There’s some riding in 1996’s Chain Reaction, including one scene in which he manages to outrun an exploding hydrogen reactor. He’s technically on a bike in John Wick 3 while battling bad guys, but that was all done while stationary in front of a green screen. He has no interest in shoehorning Arches into his movies, though a couple of Arches are featured in the futuristic 2020 video game Cyberpunk 2077, in which he also played a major role.

Reeves says there’s a brief motorcycle scene in the upcoming John Wick 4, a movie whose eventual existence might have been laughed at when the original film debuted. Despite the series’ current status as an unstoppable franchise juggernaut, it originally wasn’t even planned as a franchise—and it certainly didn’t appear destined to be one after John Wick received a somewhat tepid theatrical reception in 2014.

“It had some success in the theater, but it really became more popular in second viewings,” Reeves says. “So the studio asked if we wanted to do another one.”

Reeves does more than just kick unbelievable amounts of ass in the movies; he’s also had a hand in plotting out the sequels. The genesis of the third and fourth installments, he says, took place while he and director Chad Stahelski were on the road promoting the second and third movies, respectively.

“Generally, Chad and I cook ’em up while we’re doing press tours,” Reeves says. “We talk about what we’d do next if the current film does well. I’m like, ‘I want to ride a horse and do a horse chase!’ And Chad says, ‘Yeah, we can do it in Central Park!’”

Reeves says he doesn’t know what comes next for him, but John Wick 5 will almost certainly be an option—if he wants to do it. He’s currently developing a TV series, and maybe he’ll make the motorcycle road movie he’s long thought about making. He’ll also no doubt continue riding bikes and growing Arch because he loves doing both.

He says he may continue BRZRKR, the comic series he co-writes. He won’t stop helping others via his philanthropy (he declines to discuss other than to say it’s “in health and the arts”). And he’ll burnish his already-glowing reputation as, in his words, “a pretty respectful and considerate person,” because that’s how he likes to treat people.

“I’m just,” Reeves says as his mouth curls into a smirk and his arms shoot out in front of him as though he’s pleading to be believed, “a normal guy.”

via keanuworld

160 notes

·

View notes

Text

A couple of days ago, I was collecting seeds from the milkweed pods in our yard. Having not done this before, but being fully aware of the fuzzy stuff that flies out of the pods, I was battling fuzz (technically, "floss") as I was pulling off and storing the seeds. Then I got smart, and decided to cut a slit in the pods and then gently pull out the mass of floss and seeds, and then just pulling the seeds off and dropping then into the container. As I was doing that, I noticed how super soft the floss was as I pulled it fresh out of the pods, and wondered........do any clothing manufacturers use this stuff? Did a Google search, and learned....yep!

Excerpt from this story from Happy Eco News:

As consumers demand more eco-conscious apparel, brands are getting creative with natural materials that keep warmth in and environmental harm out. One unlikely hero emerging from prickly planted fields is the common milkweed—yes, literally plucked straight from the wild. While best known as the sole food source for iconic, struggling Monarch butterflies, milkweed’s hidden potential is nestled right inside its fluffy, silken floss. This fleecy fiber is an amazing natural insulator and is finding a new application in jackets, parkas, boots, and ski gloves for humans.

As outdoor apparel companies race to reduce environmental impacts, milkweed clothing insulation is proving a promising substitute for conventional insulation fillers—one aligned with cleaner agricultural systems. Its hollow-cored fluff offers an animal-friendly, biodegradable alternative to goose down. Unlike petroleum-based synthetics like polyester fibers, milkweed fills garments with a regeneratively sourced material that decomposes rather than lingering for centuries in landfills.

With conscious consumerism accelerating across industries, apparel buyers now consider impacts far beyond cost and quality when evaluating purchases. An unlikely hero from both suffering North American grasslands and climate crosshairs is rapidly gaining traction as a sustainable insulation material – common milkweed floss. Beyond keeping heat in and winter out with insulating performance rivaling goose down, milkweed rates exceptionally on multiple sustainability indicators resonant with eco-conscious consumers.

As a native perennial thriving on marginal lands, milkweed flourishing requires no irrigation, fertilizers or pesticides – regrowing reliably year after year. From a toxicity and allergen standpoint, milkweed avoids issues associated with many synthetic insulations or down. And supporting milkweed crop expansion helps reverse monarch butterfly declines blamed on agricultural habitat loss. For shoppers concerned over microplastics shedding into waterways from standard fleece, milkweed offers a soft, homegrown, biodegradable alternative. In short, milkweed checks all the boxes for socially mindful consumers seeking future-focused apparel that balances functionality with ethical, regenerative supply supporting threatened pollinators.

Signaling the momentum of milkweed clothing insulation, major brands like Patagonia are incorporating the fluff through novel partnerships with companies like Vegeto Textiles. Dedicated milkweed plantings bandwidth habitat zones while fibers make their way into garments. Other types of textile manufacturers are also jumping on board, some with announced plans to insulate blankets and quilts with milkweed.

Still, despite its promise, milkweed clothing insulation remains in its infancy. Technological barriers to processing millions of floss strands into a stable textile filling have just recently been worked out. Machinery and techniques to update this long-known application concept into a scalable commercial reality. Companies have worked for years honing best practices for taking raw milkweed fluff through cleaning, drying, and fiber alignment steps to transform fuzzy floss into outdoor-ready filling. Advancements in the coming decade will further improve integration potential across diverse textile products, opening doors for milkweed clothing insulation in everything from t-shirts to winter boots.

15 notes

·

View notes

Text

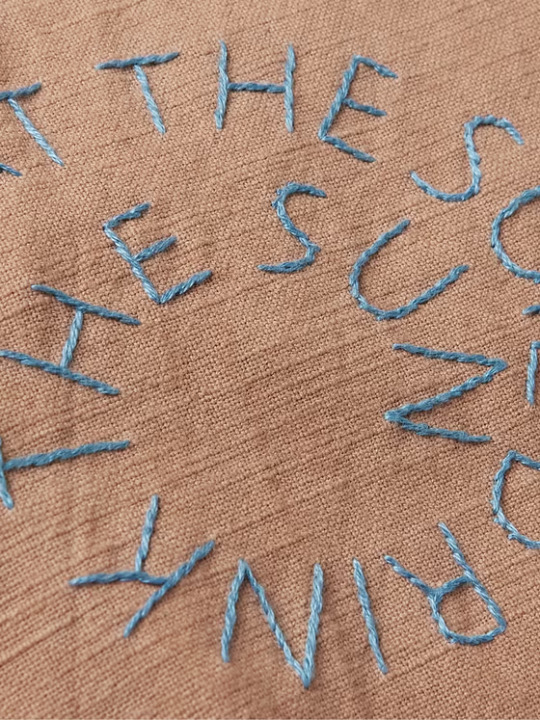

I cannot believe she put him in a jacket from a brand called “Story MFG” - Literally “STORY MANUFACTURING”

With “MFG” down one sleeve, a sun on the other sleeve, and “Drink The Sun” on the back.

Drink. The. Sun.

#gaylor swift#gaylor#taylor swift#midnights#gaylor twitter#ts10 midnights#kaylor#hits different#karlie kloss#taylor karlie#lavender haze#anti hero#lavender haze music video

155 notes

·

View notes

Text

What Are You

Does anyone remember that time I said I had an AU for Guilty Gear? Yeah I don't really have much of an explanation for this beyond it was a test of that AU that I wanted to write that;s evolved into...this.

So yeah um, this has been sitting in my drafts for -checks notes- at least a few months??? I really wanted to get it out much earlier than now but tbh I'm just glad it's finally done so have this nearly 3000 word thing before I overthink it.

Heat burned in his eyes and throughout his chest. Smoky embers rolled through his throat, coating his tongue in ash and soot. Strain filtered through his forearms, resting hot on the shoulder. He shoved harder, grip tight around the wrench.

Absolutely nothing. The bolt remained as steadfast as any rusty piece of crap would be from lack of care.

His brow pinched tight. A deep frustrated breath heaved in his chest as a trickle of sweat rolled down his temple, "Hng...dammit.." He tugs the wrench free, staring at the thing with a harsh scowl.

"Still struggling down there, hothead?"

He rolled his eyes almost good naturedly-not that you could see, "Shut up. I'm making progress, quite making fun of me." He brushed the back of his hand against his cheek, smearing something viscous but he ignored it. The headband had been an oversight, as he meant to take it off before getting under his little project, but at least the leather kept the sweat out of his eyes

You still laughed at him while kicking your feet, "Maybe I will when you're not getting covered in grease and let us both get something to eat for once!"

He huffed, "It's not that simple. Can;t just force the damn thing, it takes a careful touch. One wrong move and," Metal pings sharply right into his ear, but it proves his point as the exhaust rocks softly against his flick, "This thing goes right into my face."

He hears your hair rustle as you push it behind your ear nonchalantly, "And? You've been punched real hard by a car once."

"Got hit by a car."

"Semantics aren't important." Your shadow on the wall waves off his scoff, "You'll be fine."

"I will. This won't." He picks up the end of the topic of discussion to hold it out from underneath the motorcycle, "This thing was half a month's payment to get and I don't feel like remaking it. And the manufacturer is out of business for the rest of the year, so there's no replacement either." The recently polished pipe squeaks as he props it back onto his shoulder, hanging precariously just over his face.

The singular reason why it couldn't just be pushed out of his way was staring him in the face with all it's rusted stubbornness-a joint from the old exhaust kit still set in place. He'd left it when first starting since it wasn't too important yet, but now he kind of wished he did. The rust had soldered the bolt into the frame and he couldn't replace that without completely fucking up the whole shape of the bike. If the section he was on wasn't a support brace he wouldn't have been worried about it, but there it was right in his face like a fist to the nose and here he was trying to fix it.

To add insult to injury it was quarter past noon, right in the heat of the day. The sunlight from the garage's ratty window was like a branding pole right across his chest, not held back in the slightest by the missing slats in the already broken blinds. He'd already sweat through his one good shirt-thankful for the one time he thought ahead and took off his vest for 'safety reasons' that only meant for the jacket to sustain the least amount of damage possible.

"Yeah fair enough on that end I guess." Your small sigh stills his hand before he can pick up the wrench again, "The Dragoons have been getting worse." And he almost rolled his eyes, huffing under his breath.

Dragoons. Half human, half dragon. Monsters in the form of men that only knew destruction. The reason for the current lockdown that pushed him off the King's work list for a while. For his own sake, he said.

Bullshit.

His grip on the wrench tightened, "Yeah. Like always." The frame creaked a bit as he pushed himself into place, the old wheels on the cart he laid on rattling under his back, "Bastards love to make things worse whenever they crawl out of their holes." Like keep him from getting an actual set of jacks for the bike over his head and leaving him to resort to ram-shackling the thing on top of scrap and a pile of real thick phone books.

You only hummed. The tips of your steel toed boots flicked in and out from behind the front wheel. You;d sat yourself on one of the many old crates he had yet to haul out of this old garage, leaning back and kicking up your heels like you owned the place. He didn;t doubt you came without your phone, which he did hear you tap away on again once you stopped answering. So he turned back to the subject in his hands-a stubborn bolt that refused to move.

It was after a few minutes of him quietly struggling to himself that you spoke up, clearly bored with whatever you had been entertaining yourself with before, "Though it's kind of confusing to me." He lets out a tight hum for you continue, "How are you different?"

He grunts through his teeth-damn this thing refused to move, "Different? The Hell are you on about?"

"I mean." You hesitate, huffing as you gather your bearings, "Why aren't you?" Your heels tap against the crate as you swing them.

"Why aren't I what? Just say it." He let too much aggression slip as he tried again to make the bolt just fucking move. Fucking Hell, he was moments away from just wrenching the whole lot off and calling it a day. Support frame be damned he wasn't dealing with this for much longer.

"Dangerous. Like the other Dragoons."

Immediately tension locks his hands into place, wrench handle digging into his palm. Ice pours into his veins as if the sun decided it wasn't summer anymore and slipped right into winter. Wide eyes glance towards where you sat, frantic, "What."

If his bark affected you there was no way he could tell from where he sat. Your boots shuffled against the crate, steel lined heels clacking together, “You have the Dragon Install, which is a Dragoon ability. The marks on your neck are a dead give away, too. You're also stubborn, short tempered, and itching for a fight at a moments notice. Just like one of them.” Each finger he heard you flick out made his shoulders flinch almost imperceptibly to you, but for him he felt each one like a tick of a clock.

A self conscious hand left the wrench to brush along the stripes decorating the sides of his neck and throat, normally covered by the jacket's collar. The jacket he had stupidly tossed aside so he could drag himself underneath his project without worry. Right.

Fuck him.

He forced his hand back onto the wrench. Change topic, change topic, ”Dragoons are assholes that can't keep their heads on long enough to hold a conversation. Mostly they're known for their rampant destruction of a lot of big cities.“ Frantic he scanned around for something, anything to busy his other hand with so you wouldn't notice his pause-or at least hopefully, you'd brush it off and move on like he did, ”You did go to school at one point right.“ The question wasn't as smooth as he wanted it to be but it would have to do as he rummaged in the junk next to him.

You picked up the topic change. He knew you did. The sudden lurch forwards was perfectly aligned with the indignant scowl you always gave him when he prodded at your intelligence ”Hey I was homeschooled, asshole. I know enough.“

A little huff pulled the corner of his mouth, "Ya sure about that? I remember having to tell you about the older generations of that tech menace you call a phone." Pliers found his hand and lifted out of the mess on the floor. Without thinking too much on it he clasped the teeth around the wrench's handle.

"And? I didn;t take tech classes in college, along with half the population in the city." Your shadow waves away the comment and sweeps towards the door well out of his line of sight.

He leers at your image, grip tightening as he pushed, "You. College. Really."

"Yes really, jackass. I did manage to get in like every other half-baked professional we work with."

”Not to get anything better than a-“ Metal snapped much too loudly and right into his face, ”FUCK-! Shit….dammit.“ The bitter taste of now twisted steel bit at his tongue as the flecks scattered onto the garage floor beneath him. Even the wrench flung itself away as if to escape blame while it clattered along the floor.

”You good down there?“

”Yeah..Just fucked it up.“ He brushed the metal off his face as best he could, though a faint sting laced his eyes, ”Nothing new down here. Old piece of shit still has it out for me.“ With a scowl towards the skeletal frame braced above him he assessed the damage.

While the frame had been scraped bad, nothing was too out of order. The bolt's remains fell out of the socket with a tug from the pliers still in his hand, a mangled mess of threaded steel reduced to just a nub. He didn't really care where the rest of it went-with his luck it exploded from the force he exherted, which was fantastic. With the exhaust pipe in the other hand he shoved it up further under the chasis until it braced onto the floor over his head-not an ideal place for it, granted, as it could twist up the metal in some way, but it was better than on him or lost in the mess that was this garage's floor.

But it was your snickering that made him shove against his bike's suspended frame, the cart’s wheels rattling beneath him as he looked at you with a deep frown, ”Shut the Hell up, asshole.“ Slowly sitting up he scrubbed his very likely grease covered fingers over his eyes, probably smearing black over his face in the process, ”You don't even care that I got metal in my eyes, do you?”

You just grinned at him, leather jacket squeaking as you shrugged, “Nah, I know you're fine. Not like I haven't seen you deal with worse.” Your gaze stays on him even though he gives you a glare, narrowing onto that smug little tilt of your lips for a bit too long while you go back to picking at the peeling patch on your arm.

He grunts, getting up from the cart, “Ya sure about that, runt? Could have got a real big shard in my eye and you would be laughing about it. Real mature of you to make fun of me while I could be bleeding on the floor.” Damn, his neck ached. Granted he was laying down for longer than normal, but it rarely got this bad. It pulled on his shoulders while he rested a hand over the knot at the base of his neck and tugged hard-the nice pop rolling through his spine deeply satisfying.

“But you wouldn't because Dragoons don't get hurt that easily.”

He huffed, long and loud. Again with that. “I told you, I;m not a Dragoon.” Dropping the bolt into the scrap pile he starts digging into the drawers of a donated file cabinet that was being filled with anything but, “I'm not a mindless freak like they are.”

Perhaps you felt merciful today because once his sharp retort left him you fell silent. A small victory. Unfortunately the natural desire to ignore the current problem now left him painfully aware of just how bad he’d let this borrowed garage get. The file cabinet was the oldest piece he had-a surprising feat, as the building was at least a few decades- filled with more rust than whatever he had that had spent too much time lying around on the floor and needed a place to be stuffed into. And it's convenience was also the problem-there was more than just spare bolts in this thing. It was practically bursting with random crap he didn’t need when he had it but didn’t want to deal with. It was less an organization method and more a way to ignore the mess.

And clearly, an excuse not to continue the topic.

He'd never admit to the unease roiling in his gut. Waiting was not his thing-neither was digging through old crap in the waning hope you'd drop the idea niggling in your head for something he wanted to be bothered by.

”So.“

But you were, in fact, the most stubborn human being he's ever met.

He sighed, rolling his head back behind his shoulders, “What now.” He grumbled, hand still halfway into a new drawer.

“I'm getting to it, jerk, give me a second” Again he snorted as you huffed. But when you weren't immediately going down another one of your common rantings about the king you both worked under-which would be a blessing in this case, he'd take anything else right now-he grew wary.

Yet you continued.

”I know of the dragons. Big ugly things that come from the rifts to the Otherside, some unknown dimension parallel to our own where it's similar but wrong in a way.” Your boots tamp onto the concrete as you hop off the crate, ”People think that humans were there once from relics, but it;s possible the dragons either ate them all or did something to get rid of them.“ Steps clunk across the garage floor as you approached slowly, almost cautiously, “I know you're not a dragon. That much is obvious." He rolled his eyes, "You've also stated that you're not a Dragoon, but you have a lot of similar abilities that Dragoons have-short temper, brash personality, preference towards destruction and the like.” His ears twitch at each finger you flick out, repeating the count you’d made before, “Yet at the same time you have control over your rage. Instead of reaping havoc, you direct it, almost like a gun, towards whoever you're fighting. In fact I don't think I've ever seen you get super angry at anything that isn’t that hunk of junk you call a project over there.” Air swishes, like you'd tossed a thumb over your shoulder.

He’s frozen in place, staring blankly at the cabinet. It’s all too much. How had he not noticed how closely you were paying attention. How well you’d been watching his every move-sure, he couldn’t exactly call you a slacker, but you’d rarely made it feel like you were a threat.

And yet he should have. It was written in your title, your name.

Hunter. Dragon Killer.

Harmless wasn’t in the job description.

But…could he really call you dangerous? Yes, you’d read out his failed cover up like a book on a shelf, but it wasn’t with malice or even disappointment. Though you sounded a bit exasperated, it wasn’t what stood out-just a backdrop to something softer, lighter despite the weight of them. Something almost like…

Curiosity.

“So my question is, if you're not a dragon, or even a Dragoon, then…” A subtle shift of your hair as if you’d tilted your head makes his breath catch in his chest, ”..What are you?“

The words are there. They stick in his throat like honey-sweet, sickly so, a coat of lies he could use to cover the whole truth and hide it away before it's ever known. He could speak them now, cover his back and run away again.

But he can't. He's already gone too far. Said too much, let you in too soon. If he backed out now, it would only make it worse for the both of you. In his eyes, there’s two ways this can go. Either you get it from him, or you take the unbelievably stupid risk of finding someone else to answer-neither of which are on his good list of ideas.

Well, at least one was a definite no-go. The other not so much, but he couldn't guarantee how flaky he could get.

Instead he sighs. Air hotter than the setting sun boils against his lips, what little condensation a desert could procure steaming away before his face in a puff. With a collecting breath he turns, face carefully neutral. The aged black shirt stretches to accommodate the tight cords of muscle as he crosses his arms, workbench creaking as he leans back against it.

Looking you in the eye he forces the words to leave his lips, ”A Drago.“

He sees the gears in your head working. Little flicks of confusion as you glance about, unsure whether to maintain his intense stare or gather information yourself by whatever he'd hung up on the walls. But the garage's scattered remnants of memorabilia wouldn't elaborate on his words, thus forcing you to turn back to him. And with a soft swallow, you ask the words he didn't want to answer yet knew he had to, ”…What's a Drago.“

And here it would fall apart.

”A dragon turned human.“

10 notes

·

View notes

Text

wang yibo - announced as chief spokesperson of YAYA

From the stage to the screen to the track, he has experienced multiple life roles, and he has gone all out for his love; from the first manufacturer of down jackets in China to the global leader in down jacket sales, it has used quality to create classics. Welcome @UNIQ-王一博 to become the chief spokesperson of YAYA brand.

#wang yibo#it’s v interesting to me how he’s picking up homegrown or national brands#that’s actually smart considering the politics of the world#hahahahahahha that got v deep#but anyway#CONGRATULATIONS WYB!!!!!#so many yibis!!!!!!!!

34 notes

·

View notes

Text

Clamshell [0.1]

Masterlist

A/N: Hello, I'm back. Still working on some old drafts and had some requests for some new ideas. I'll get to them for sure! I thought up a cute little backstory for how Remington met Vera -- back before she had any idea of this robbing business. And this chapter includes an actual bank robbery now. Happy reading!

--

Las Vegas, 2017

Remington had smoked the same brand of cigarettes from the time he was thirteen, and he hated the way they had been reformatted and manufactured. The taste and zing had been dulled down in order to meet the standard regulations of whatever federal ball-busting association had these cigarette companies bent over a desk. Perhaps he could still enjoy them the same way if he found the same thrill at thirteen, rifling through his older brother's things one day to knocking some off to seem cool to his friends.

The cigarette flew from his fingertips and was lost in the blustering wind, try as it might it could not tousle through the layers of hairspray he had sprayed on his spikes that morning. Down the freeway he and his brothers drove, feeling as free as the birds that migrated above their heads, unaware and uncaring for the chaos and treachery they may find in the big city. Sebastian had to go to work, because of course someone had to pay their bills legitimately; though Emerson and Remington were off to pull some work of their own.

Their long time confidant and friend, Andrew was driving upfront in their beaten up, unassuming mini van, his shaggy mullet was cloistered under a straw hat. Emerson wasn't much of a fan of said hat.

"You look like a farmer," he pointed out for perhaps the fifth time that morning.

Andrew scoffed, glaring at him through the rearview mirror, "Because you look so much less unassuming in yours," he was referring to Emerson's floppy, wide brimmed slouch hat.

"Well, I'm not gonna' be wearing it for the job," he replied.

"Just leave him alone, he likes it," Remington cut in, trying to sprawl his long legs out in the back seat.

Sebastian was sat shot gun, dressed in his jacket for his line cook's job. He kept glancing back at his younger brothers, seemingly uneasy.

"Are you sure you guys wanna' do this without me?" he asked, perhaps for the third time that morning. His brothers had been planning this job for months, a smaller heist in comparison to others they've pulled, but the diner Sebastian worked for was severely short staffed and he was being scheduled more and more until more bodies could be hired. Of course, neither of them could afford to lose their jobs, so Sebastian had to put his heist planning to a pause while he covered as many shifts as he could.

While they figured they could wait this out, Remington and Emerson were eager for another job soon enough. And so, they had spent some time drawing up plans for a smaller bak heist. After all, living in Vegas was no cheap and easy feat for anyone.

"Of course we are, we've planned this perfectly," Emerson assured, turning to his brother, "Right?"

"Right," Remington sat up and reached over to grab Sebastian's shoulders, "We got it all under control, you just do your thing; flip your burgers, dress your salads, pour in half a bag of sugar into your hollandaise sauce,"

"I wouldn't if I didn't have to," Sebastian grumbled back, looking forward as Andrew pulled over to the cafe he worked at. Sebastian turned in his seat again, "You guys be careful, and don't do anything foolish for the love of God,"

Remington put his hand over his heart, "Swear on mom and dad's graves, we'll be good,"

"Better than that, we'll be slick," Emerson grinned.

Still unconvinced, Sebastian turned to Andrew with grim reprieve, "Make sure they don't get themselves killed,"

"You got it," Andrew gave him a high-five, "I'll come pick you up later,"

Sebastian hopped out and hadn't even shut the door before the minivan pulled out again. They travelled through the smaller outskirt suburb of Vegas, where the main strip was still within clear view. Remington and Emerson were getting their gear together in the meantime, guns, duffels, and of course, their balaclavas.

The Lieseil Funds Bank was a smaller bank chain, handling business ventures from blue-collar start ups to college-fund investment plans. It was a more obscure target that wouldn't be a considered target for crimes such as this, and it sat right across from Bobbie Trap's Pub. It was there one would find a raucous commotion emanating from the back of house, a young waitress being scolded by her manager.

Of course, it wasn't initially the waitress' fault, a customer, still drunk from the night previous, decided to try and take a handful of her behind. But of course, when she turned to defend herself, one thing led to another and she tossed a glass of water over his head. Despite how she tried to explain her case, her boss rattled on about how irresponsible and hysterical she was, so he took her by the arm and practically dragged her out of the establishment and threw her out onto the street, tossing her ratty apron after her.

"Go be somebody else's problem, Vera!" and he slammed the door in her face.

That was how Vera found herself sitting on the sidewalk outside of the bank with said ratty apron and her scuffed up converse kicking at the pavement. This was the third job she had lost in four months and she was cussing herself out for being so reactive and explosive. Just her luck anyhow, the volunteer at the women's shelter had lobbied hard for her to get that stupid waitressing job. Never the less, seeing the inevitable disappointment on the volunteer's face when she came crawling back would be absolutely gruelling.

She ran a hand through her tangled, dry hair, her brain racing for some sort of answer to her predicament, she hadn't paid any mind to the minivan that had pulled up in front of Bobie's.

Remington glared through hooded eyes at the bank, mentally flashing through the blueprints that Emerson had drawn up of the building, running through the response time it would take for police. He looked to Emerson, his face covered in his own lint-littered balaclava, then to Andrew, his head down and his straw hat pulled just over his eyes. Morning rush hour was over and the street was relatively quiet, perfect for their quick getaway.

They were just about to hop out when a man suddenly emerged from the local bar, his head down as he counted the stack of money bills in his hand, clearly out for a deposit. He didn't even give the random girl on the corner a second glance. Remington licked his lips hungrily as he watched the man cross the street and head into the bank. Sebastian was going to be so proud of their score.

With one final bow of confidence, Remington and Emerson jumped out of the minivan and hustled across the street, slipping into the bank. The few people within the bank paid no mind until Remington held up his automatic weapon and fired a few rounds into the ceiling. There were screams of terror, plaguing confusion as bank tellers and bystanders ducked for cover. And of course, the one security guard they had proved to me less than efficient as Emerson knocked him out with one swift blow from his gun.

Remington, ever one for great theatrics, leapt onto one of his desks, brandishing his weapon and tossing the duffel at the bank teller, "Ladies and gentlemen! I beg you all to remain calm, you are not in immediate danger! However, if it wasn't obvious: this is a robbery!"

Vera had her head in her hands, none the wiser to the chaos within the bank until she heard the first gunshots. The windows were dusty but when she turned around she could make out some of the pandemonium from inside, and her heart began to race as she realized she was witnessing a full scale bank robbery. It was so close, all playing out in front of her and yet she felt like she was watching some sort of scene from a movie.

"Holy shit," what should she do, call the police? Maybe somebody already had? All banks had those little panic buttons, right? There was more yelling, some banging, and Vera watched in disbelief as one of the robbers leapt onto the desk, almost performative in his clear threat to the public. She was frozen, out of fear or fascination she wasn't sure, but all Vera could bring herself to do was watch.

Remington and Emerson had gathered what money they could, as well as other valuable personal pieces and spare cash the customers had on them. The man from the street had a cool five hundred dollars he had a hard time letting go off, but Remington shoved him down and cleared up as much of it as he could before he and Emerson took off.

Not even five minutes passed before sirens could be heard in the distance, and the robbers were making out with their loot: two big duffels full of cash. The time had come for Vera, she started crossing the street to get herself away from the chaos. The first one raced clumsily towards the idling minivan and the second was close on his heels, or he would've been if one of the bank bystanders hadn't chased after him.

"You get back here! Vera! Stop him!" Vera was shocked to find her boss coming after the second robber with a clenched fist. He was closing in on him, and Vera wasn't sure what had come over her, glancing between the robber and the minivan his partners were waiting in, and then she glanced at her former boss. Her petty anger riled up within in, and as quickly as she could, she put out her foot and watched with with subtle glee as he face planted into the road.

Remington stopped short when he heard the thud, staring in disbelief as he saw the large man trying to gather his wits. His gaze then shifted to the girl who had clearly tripped him, their eyes locked. She was a young, unassuming type, slender and yet she had a mousy attractiveness.

"Move, man!" Emerson called from the van. Remington only had time to throw one callous wink at the girl before he leapt into the van, the dark ink of an X on his right knuckle fleeting as the van door closed behind him. About a minute later two police cruisers arrived, one of them taking off in the van's general direction.

When he had recovered, Vera's former boss dusted himself off, his mean gaze narrowing on the young girl. He stomped up to her, seething like a bull in Pamplona.

"What is the matter with you!" he shoved her, "You let them get away with my money! Are you just that stupid?!"

Vera, playing up her nonchalance, simply shrugged and smiled politely, "I don't know what you're talking about. Maybe you should go be someone else's problem?" and with that, she turned on her heel and walked in the general direction of the women's shelter.

The Bastards crew had made a hasty, but clean getaway from the cops, and Sebastian couldn't deny how impressed he was with his brothers' spoils. They celebrated greatly with some cheap bottles of gin and pizza, though Remington found himself too preoccupied for celebrating. That girl had intercepted and nested in his brain, he had laid eyes upon her just for a moment yet he could see her so clearly. She was reminiscent of a manic pixie dream girl from a Bertolucci film, yet her dim confidence and outlandish pulse reactions were outstanding.

He sat on the porch of the bungalow they shared, a shabby little place in a run down lower-middle class neighbourhood. The air was dry, the heat unbearably humid, though it didn't stop Remington from enjoying his beer as he looked out into the saturated sunset. He had never found himself so curious over someone, especially over a girl. Why had she decided to help him, who was she? And of course, what bone did she have to pick with that bar man?

Out of all the chaos from the day and the questions spinning in his brain, he at least had one answer: Vera. It was a pretty name for a pretty girl, and as he lay in bed that night, tossing the sheets on and off because it was just too damn hot, Remington decided that he wanted to try and find her, to thank her at least. Would she react badly? Maybe. Would Sebastian absolutely end him if he found out? For sure. Never the less, Remington liked risks, and he certainly hadn't met a challenge he wasn't willing to take on.

And as he showered off the night time sweat in lukewarm water, he had successfully made up his mind.

Vera had crawled back to the women's shelter with her tail between her legs, having to sheepishly explain to the volunteers how she'd lost yet another job. Despite their clear frustration with her, they promised they were going to help find her something that would stick.

Empty promises, empty promises.

All night she couldn't sleep, tossing and turning in her brick-hard bed as sleep eluded her. Every time she closed her eyes she kept reliving the chaos from the morning. She hadn't told the volunteers about it, they would panic and worry about Vera being a witness and wonder if she was a liability to the rest of the girls in the shelter. She had seen it before with girls who had witnessed things they shouldn't have, and of course in Las Vegas, there were a plethora of things you would often wish you never had to see.

However, Vera found she wasn't traumatized so much as she was fascinated by it all. It all happened so fast and yet she could remember every detail so clearly, how sharp the gunshots were, how the clear leader of the two was so ostentatious in his crime, how he even took the time to stop and wink her, almost as a thank-you for letting them get away. She couldn't see his face of course, but she could remember those eyes so well; chilling, almond in shape and dark to the point where his eyes almost appeared to be blacked out entirely. Nevertheless, Vera found she wasn't afraid; perhaps she had become so numb to the tumultuous ongoings within the city? Or deep down she was content with the fact that the balaclava-clad stranger wasn't going to hurt her. Not like she would know him if she passed him on the street.

In the sizzling afternoon heat, Vera was wandering an outlet market, a pretty inconspicuous cover as she read her magazine from the news stand. Every time she turned the page she found an ad for some luxury perfume, designer bag or exquisite jewelry piece. She ran her fingers over a bejewelled necklace that Lily Collins was wearing for Cartier, wondering how it must've felt to be and live so rich. All Vera had ever known was cold floors to sleep on and living paycheque-to-menial-paycheque.

This part of Vegas was a bit quieter than the strip, nonetheless bustling with professionals and cars would line up and funnel out to make their way to their destinations. Vera took a deep breath of cigarette smoke, dust, and exhaust, the white noise somewhat calming her. She was none the wiser to the young man standing at the street corner, his hands tucked into the pockets of his denim jeans, seeking refuge in the heat under a shaded tree, his dark eyes locked on her while his cigarette sizzled between his fingers.

"Hey! You gonna' pay for that?" the clerk at the newsstand barked at Vera. She refrained from rolling her eyes as she placed the mag back on the rack with a polite, sickening grin. The clerk came around, grumbling to himself as he had to reorganize his selection of reading material, none the wiser to Vera plucking a candy bar from the opposing display while his back was turned. But Remington found himself impressed as he followed just a few feet behind her.

Vera ate her candy bar without much thought as she skimmed the display tables of shirts and knock off hand bags. Nobody paid her a second thought, she seemed practically invisible as she was bumped and knocked aside by the bustling crowds. She flinched as an associate from the church of scientology tried to shove a pamphlet into her face, ducking swiftly towards the other end of the market. She suddenly found herself in front of a jewelry table, it was nothing too opulent, but the pieces were beautiful and Vera couldn't resist.

She picked up a simple gold necklace, the chain was delicate and in the middle hung a beautiful, pearly clamshell charm. The clerk was too busy bartering with another customer while Vera plucked the clasp apart and slipped the necklace onto herself. It was absolutely gorgeous, the cold complimented her complexion exquisitely and the clamshell glistened in the sun's reflection. Nevertheless, the price swayed Vera much more than the look could; it was forty-five dollars and Lord knew she couldn't afford anything more than a happy meal at this rate.

Remington had broke through the crowd, dodging the scientologist and finding Vera at the stand on the other side. She was twisting from side to side in the mirror, her chucks strained in the soles as she stood on her toes, she seemed almost childlike. Remington couldn't help the curious grin on his face as he debated to himself, how should he approach her? And hell, would she even bother to give him the time of day. He was a relatively good looking boy, though the city was filled with fast-talking leeches and he wouldn't blame her if she told him to buzz off.

However, Remington's opportunity hit sooner than he'd prepared for, whisked out of his head as he heard someone shout.

"Take that off!" the clerk at the jewelry display scolded Vera, making her and the few immediate customers in the vicinity jump. The slender Filipino woman charged over to her, a deep scowl carved into her face as she waved her finger at her, "You can't just take from my table and try the stuff on!"

Vera cocked a brow, "Then what's the mirror for, then?" she asked simply.

"Didn't you read the sign?" the older woman pointed her bony finger to the sign by her register: please ask before trying on jewelry was scrawled out in just legible handwriting, "You want to try? You ask me first! You could be stealing for all I know!"

"I'm not stealing it, I'm trying it on!" she snapped back.

"Are you going to buy it?" the clerk asked.

"No,"

"Then take it off!" she waved her hand at her to hurry along, "Go shop at Value Village or something, you probably can't afford this anyway!"

Vera did her best to bite her tongue as she reached for the clasp, not wanting to give in to the woman's very clear opinions of her, "Okay! Okay! Here!" she barely had a handle on the latch of the clasp before a sudden, sharp odour of cologne filled her nose, and she was surprised to see a young man taking step beside her.

"Hold on a sec, there's no need to be nasty about it," the boy told the clerk, trying to de-escalate the tension between the ladies.

"Who's being nasty! She can't buy anything so she's wasting my time!" the clerk cried, drawing a few side-glances from passer bys.

"Who said she can't buy anything?" he popped a brow, then turning to Vera, "You like the necklace?" he asked.

Vera wasn't sure as to whether she was embarrassed, scared, or relieved, seemingly having this stranger on her side. He seemed harmless enough, smiling gently and persuasive in her mannerisms. She never broke eye contact with his dark eyes, nodding slowly.

"Yeah,"

Remington's smile got wider as she nodded and he pulled out his wallet, flipping through the bills. The clerk had certainly stopped talking once she saw the wad of cash he had on him. Remington pulled out forty-five dollars and handed it to the clerk, plus a five dollar tip.

"There you go, forty-five bucks. Plus a little something for the misunderstanding," he assured her. The clerk glanced at the money, dumbfounded at first. When her train of thought finally caught up with her tongue, she placed the money into her pouch and reached for her register.

"I -- I... thank you. Uh -- here. Let me print you a receipt --"

"Don't worry about it," Remington nodded politely, subtly knocking his elbow with Vera's, "You have a good day,"

For the second day in a row, Vera felt as though she had been stuck in a hallucinatory dream. She nearly tripped over her feet as Remington nudged her to start walking, following in quick step with saucer eyes as she watched him in utter disbelief.

"You good?" was all he said, not bothering to make eye contact.

"Yeah, I guess," Vera huffed, her voice bordering on a gasp and a chuckle, "You didn't have to -- I mean -- I would've put it back no problem --"

"Don't worry, she had it coming," Remington assured her, "Besides, the pendant looks good on you,"

Vera denied the urge to reach up to clutch the clamshell, becoming frustrated at this stranger's nonchalance. Annoyed because he had been so vague and so smug, rebelliously handsome, "Okay then,"

Remington sensed her agitation and capitalized on it, "You could say 'thank you'," he said.

Vera stopped walking then, staying put on the burning cement as she glowered, "Well, who exactly am I supposed to be thanking?"

Remington turned back and extended his hand to her, smiling warmly, "I'm Remington,"

She was tentative at first, her fight, flight, or flee modes were snapping through her brain like the slides on a slot machine. Despite everything though, he did buy her an expensive necklace and so far was asking for nothing in returned. 'So far' being the optimal phrase.

So she shook his hand, "Vera. Thank you for the necklace, Remington,"

The flush in his face he blamed on the heat, but hearing his name roll off her tongue had bells going off in his ears, "You're welcome, Vera,"

They kept walking together, his hands deep in his back pockets while she fiddled with the strap on her bag.

"... So, what's the catch?"

"What catch?"

"The part where I dubiously repay you for buying me a fifty-dollar necklace,"

"You don't have to give me anything," he assured her.

Vera scoffed, "Right, you just did it out of the kindness of your heart, right?"

"You don't believe so?" he asked.

"Nobody ever does anything for free. Especially not in this city," she kicked a loose pebble across the cement.

Remington nodded, "Fair enough. How about a coffee, then?"

"That's it?"

"That's it,"

Vera shook her head, "So you're offering to buy me a coffee to in debt myself to you even more?"

"No, you can repay your debt by spending forty five minutes having coffee with me. One minute for every dollar,"

She exhaled softly, looking briefly around the market as nobody was paying them any mind. If she needed to she could slip into the crowd and disappear so easily. However, he seemed harmless for the most part, he held the aura of a curious, twenty-something young boy who was probably just out to show off and nab himself a piece of tail. Forty five minutes was nothing, after all.

"Forty five minutes, that's it?"

"That's it,"

"Swear on the bible?"

Remington simpered as he raised his left hand and placed his right hand over his chest, "Hand of God, Mary, and Joseph," he promised.

Vera's gaze flickered to the X tattoo on his knuckle, a sharp chill running up her spine. Nevertheless, the chill wasn't fear; it was a gnawing curiosity in her gut as she realized who this man actually was. Her poker face never slipped, however.

She smiled politely, "Okay. Let's go,"

#palaye royale#remington leith#emerson barrett#sebastian danzig#palaye royale imagine#remington palaye royale#remington leith imagine#original story#original female character#band imagine blog#band blog#band imagines#the bastards#fever dream

16 notes

·

View notes

Text

youtube

sweater women dress manufacturer

YS-SWEATER MANUFACTURING https://sweatermanufacturing.com

Email:[email protected]

button sweater manufacturer kids easter dress,pullover hoodie high quality,baby sweaters 0-6 months knitting,mens sweaters,cardigan sweater outfits men,lightweight sweaters for women,hooded sweater zipper sale,faux fur off shoulder sweaters,cream sweater women,fleece 3456,knit 4 below stitch,long cardigans mans,fleece trui deken,chompas para hombr nike,sueter amarillo outfit mujer,cardigan sweater women xl,sweater y camisa hombre, mohair custom knit sweaters factories,kontra k pullover,maglione per uomo,izod 1/4 zip pullover,retro fleece sweater,sueter cuero,mens quilted casual long sleeve button pullover,kids dresses for girls winter,dress vest for men vneck,v neck jumper,pullover zip sweater,sueter de mickey mouse,knit sweater hoodie, button sweater manufacturer manufacturing knit sweaters custom https://sweatermanufacturing.com/manufacturing-knit-sweaters-custom/ button sweater manufacturer wool stitched letters sweater,sueter negro png,cardigan sweater floral,chompas negras,fleece sweater vs jacket,pullover face mask,women cardigans under 10 prime,crop top half sweater,green bay packer christmas sweater,varsity cardigan sweater,sweaters hot topic,slit long skirt, boys sweaters,pantalonetas para hombre con sueter blanco,kids girls hooded sweater,khaadi sweaters,0 stern hotels,pullover amigo,pullover with zipper,patagonia down sweater,cashmere sweater 2023,chunky knitted jumper baby,sueterxxl,chompa tactica multicam, printed pullover,jumper tule dress,3 color sweater,pull a capuche,rib knit crop sweater,sweater amazon,pullover adidas,boys anime sweater, outfit sweater,maglione brand,button sweater manufacturer customization upon request woolen sweater design company https://sweatermanufacturing.com/customization-upon-request-woolen-sweater-design-company/ button sweater manufacturer sweater Made-to-order,sueters de hombr mayoreo,pleated sets,women's sweater jogging sets,spring slim sweater sleeveless vest woman,vetementsfemme pull,sueter de mujer2023 mas economicos,sweater de algodon,sweater 500 gsm wholesale,designer sweatshirts, 30 polyester,men winter floral,v sweater design,men's sweater round neck, custom hoodie,women's cardigans ireland,lucy and yak fleeces,winter man cardigan,are hoodies and sweaters the same thing,여성 스웨터 제조 공장,gilet en laine femme,sueter para hombre cuello v con botones,sweater hoodie 30k,high quality t sweaters printing,suéter verde,ladies cardigan full size,sweaters women xl,welwat sweter,quarter zip jumper,womens rainbow cardigan, button sweater manufacturer mohair blue sweater Firm https://sweatermanufacturing.com/mohair-blue-sweater-firm/ button sweater manufacturer pullover sweater fabrication,frisse truis,ladies sweater,christmas sweaters,long section knit dress,intarsia knit cotton cardigan,mohair sweater off white,sueter in spanish,q es sueter,buyuk beden,where is cardigan bay,viscosa para tejer,initial sweater

#cashmere silk custom knitted Firm#cachemire maglione pecore Firm#100 cashmere knit men company#cashmere fashion knitwear companies#mohair wool handmade sweaters company#cachemira sweater vest men companies#cashmere cotton pullover Firm#cachemire cable knitted sweaters Firm#fleeces fleece pullover hood companies#merino wool knit zip women vest Firm#100 cashmere sweater fleece for men companies#merino wool fleece sweaters Firm#merino wool pullover baby Firm#merino wool cardigans for Firm#cachemira ribbed knit sweater set company#merino wool neck cashmere Firm#cachemire bayan kazaklari company#Youtube

2 notes

·

View notes

Photo